Production

The company includes 3 modern factories. All production equipped with advanced European equipment. We use pancake lines "BECAM" and Dorayaki from MASDAC, blast freezing chambers manufactured by "ALCO", "JBT", packaging equipment from "ECI PACKAGING LIMITED", and See also Handtmann, Poly-Clip, etc.

$ 4.5 million

Investment in production development in 2020

Quality control system with tasting of each batch of product, as well as working HACCP and ISO standards - all this allows us to produce a high quality product

The development of production facilities is one of the priority directions of the company's development. In 2020, it is planned to commission new production lines that increase production capabilities by 20%.

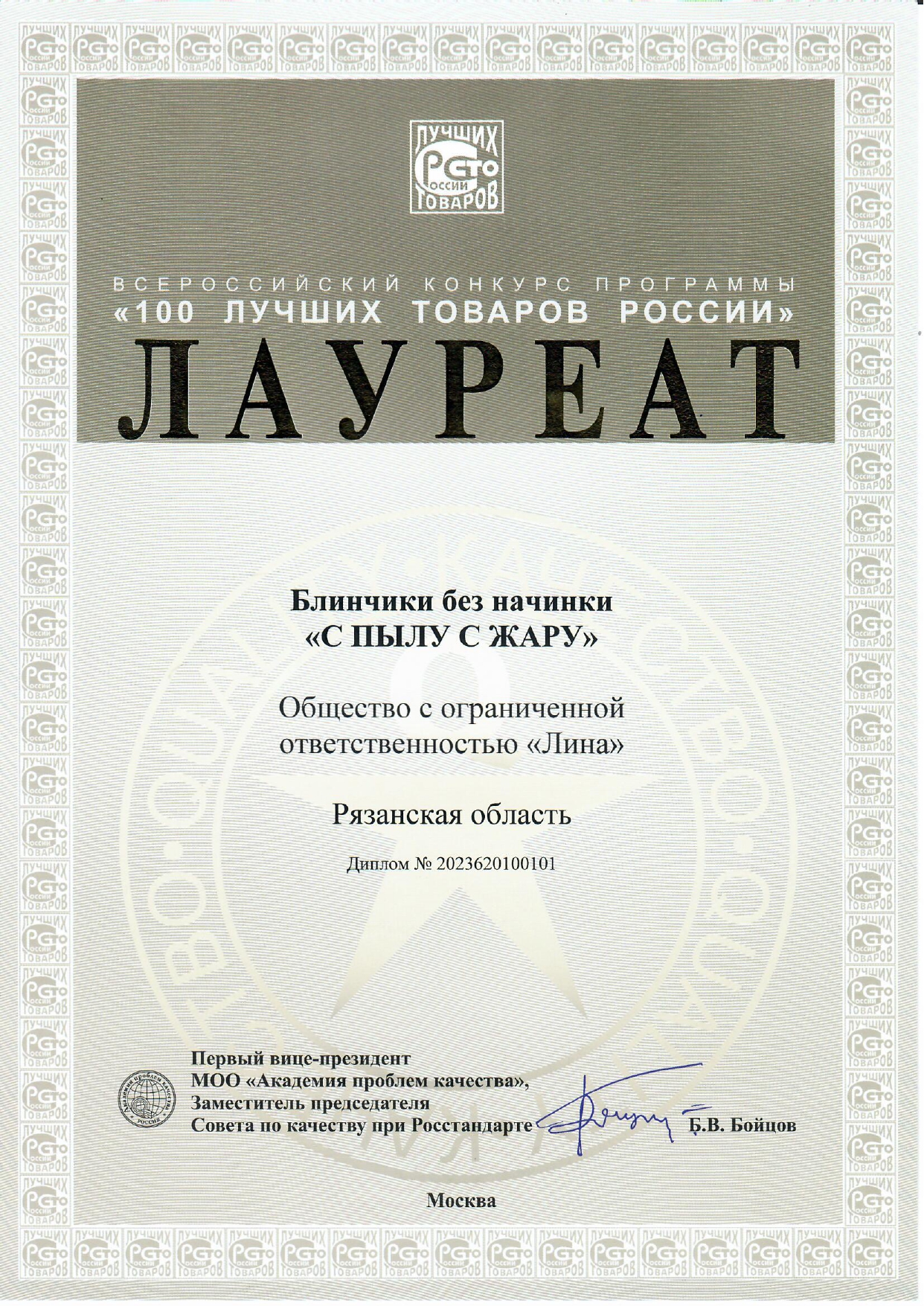

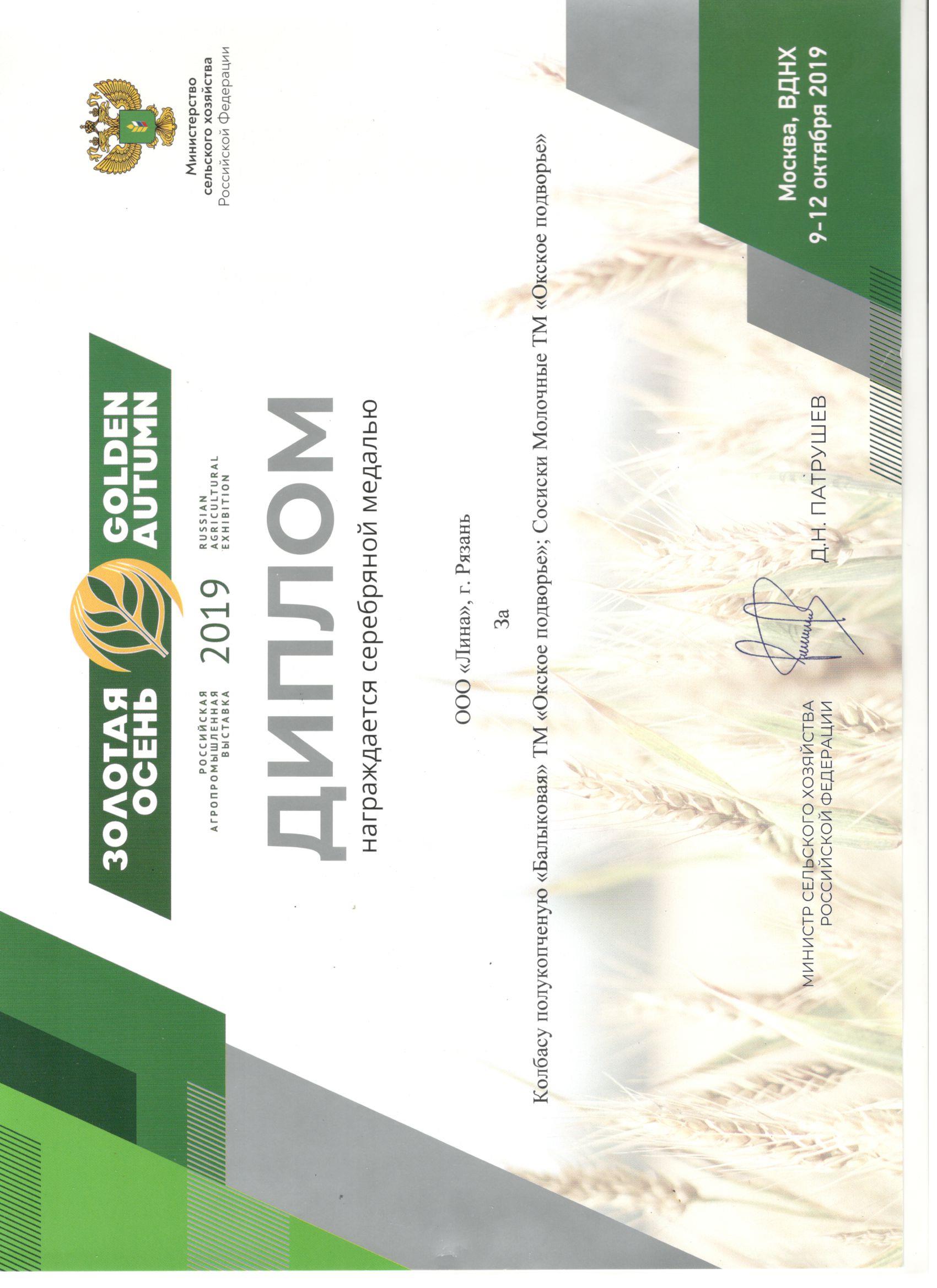

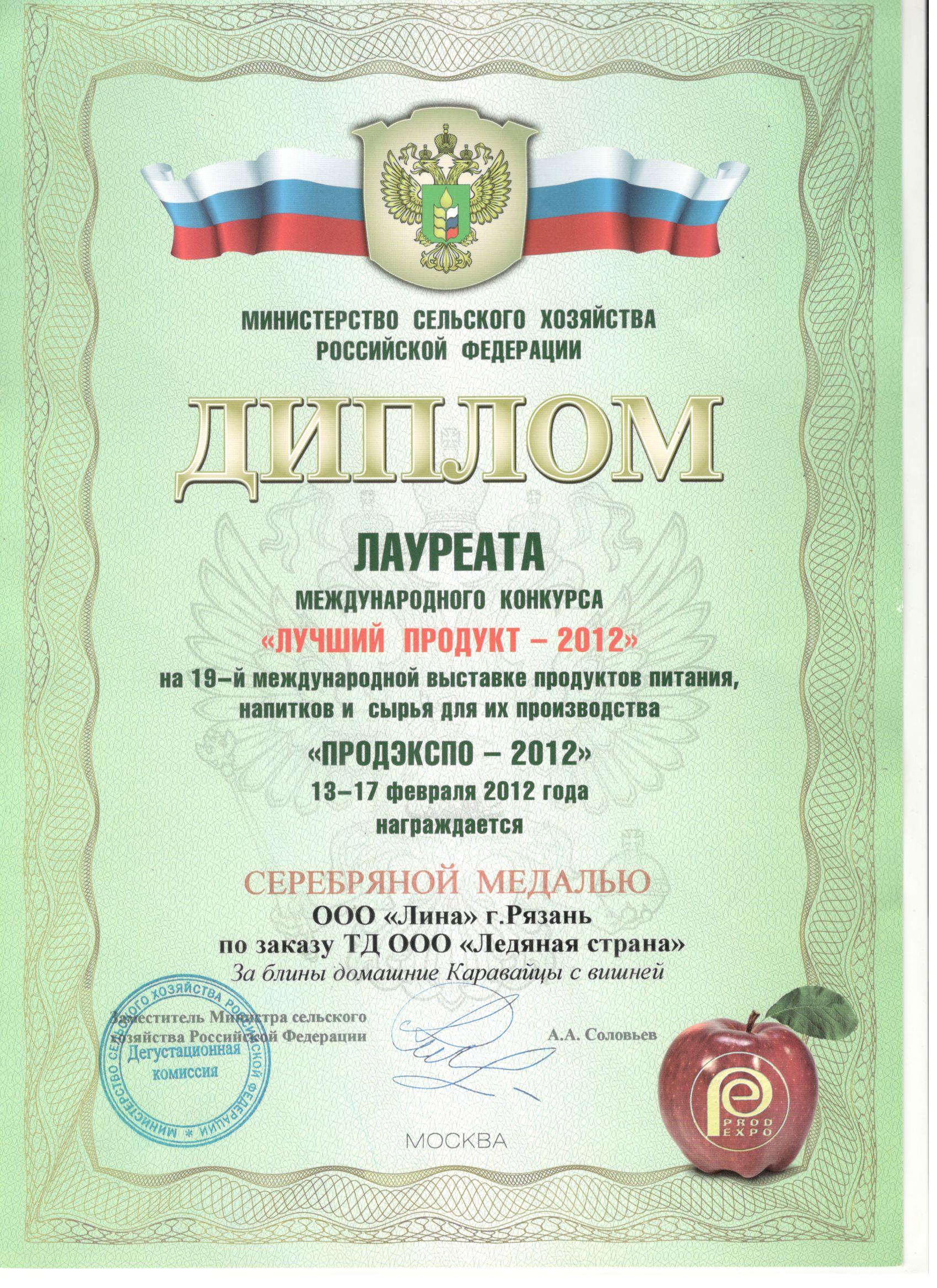

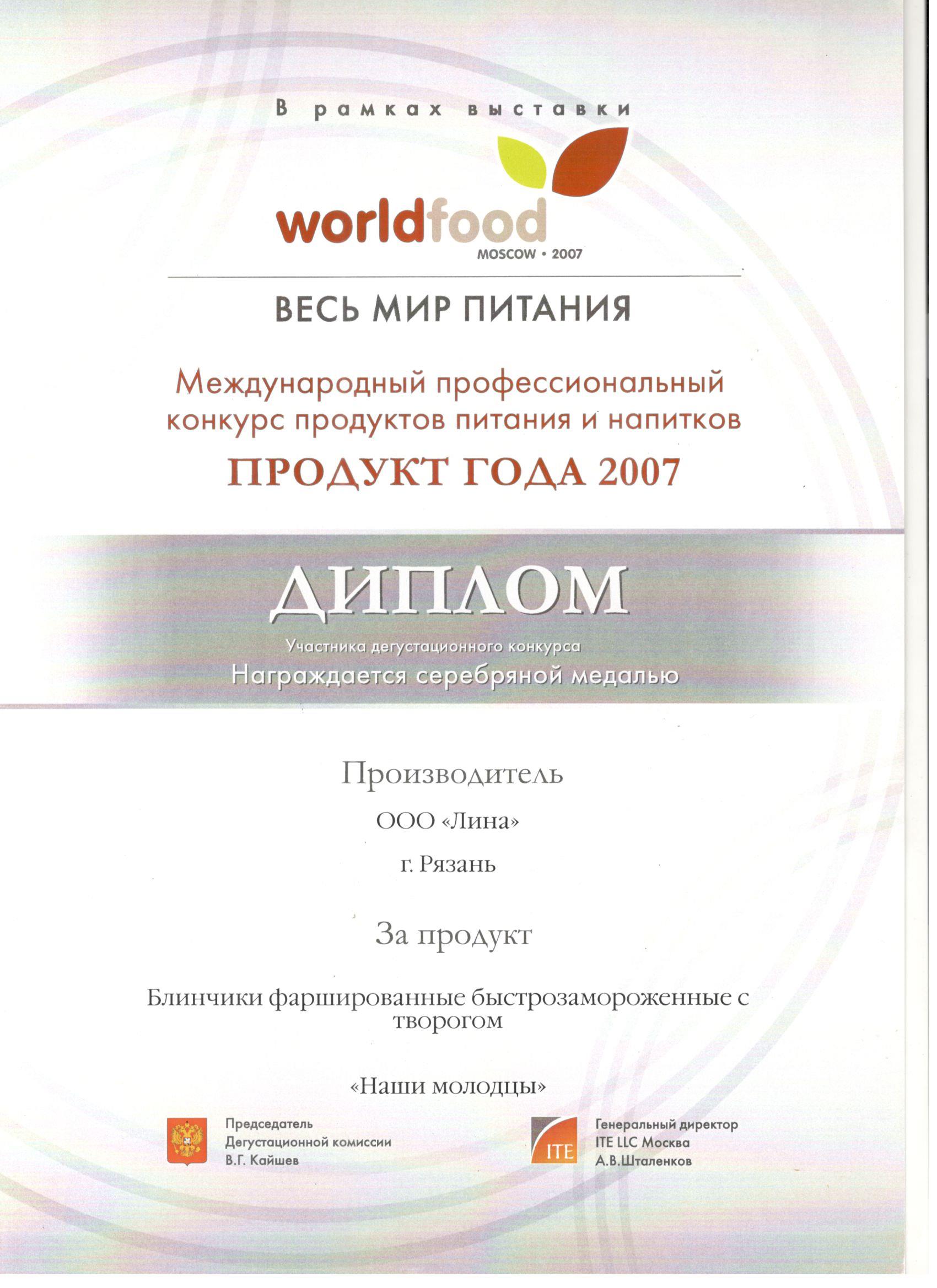

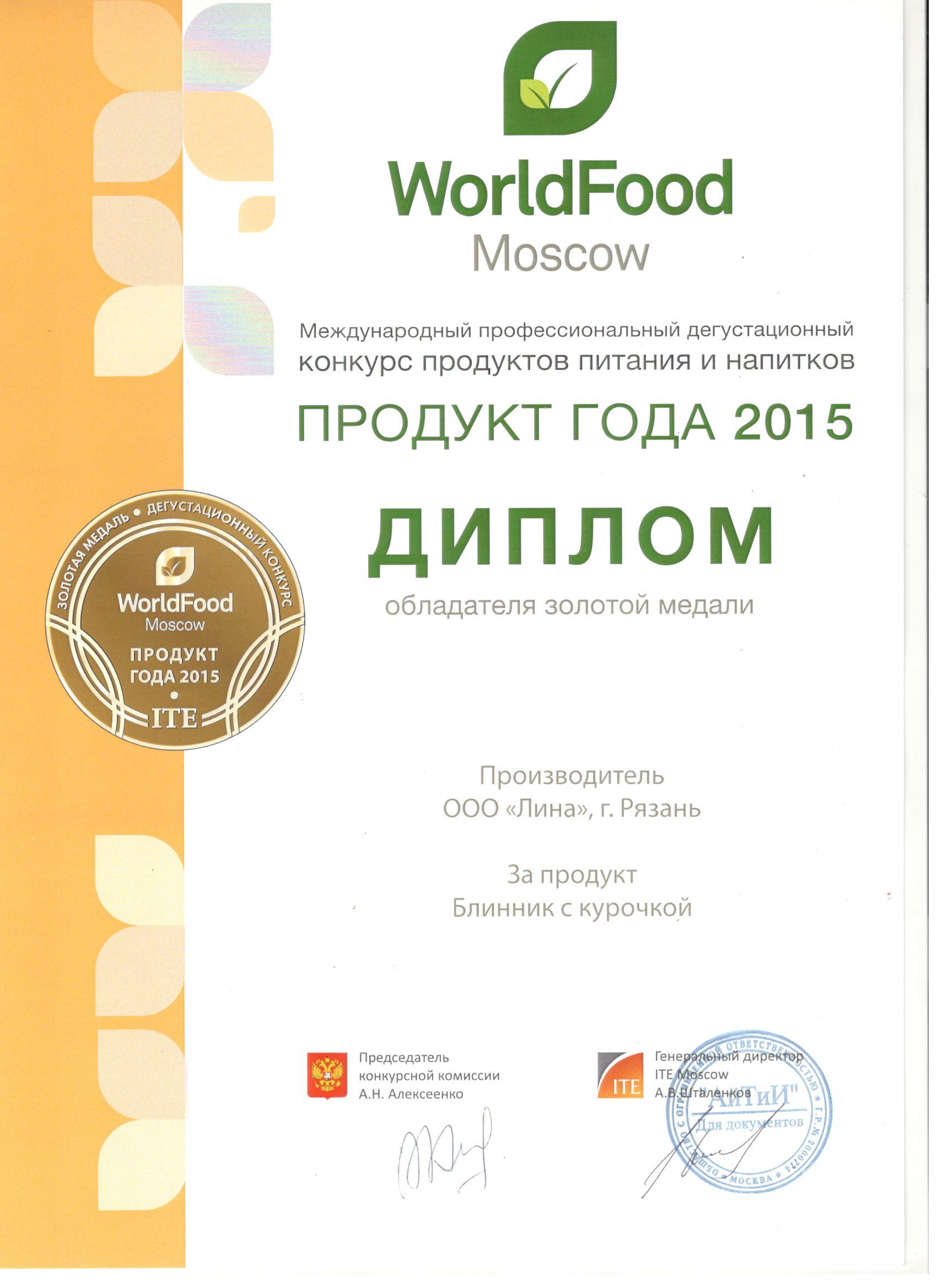

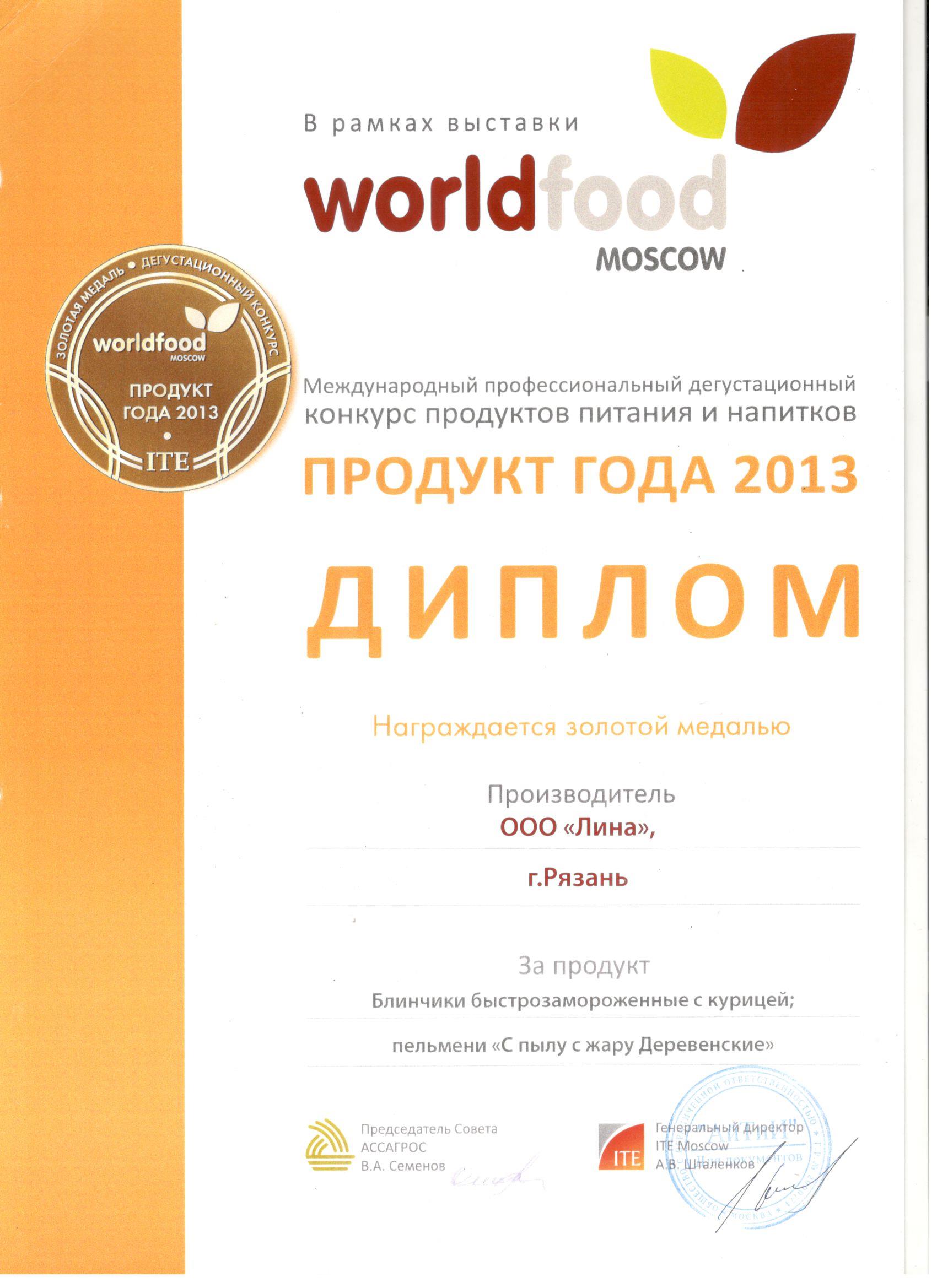

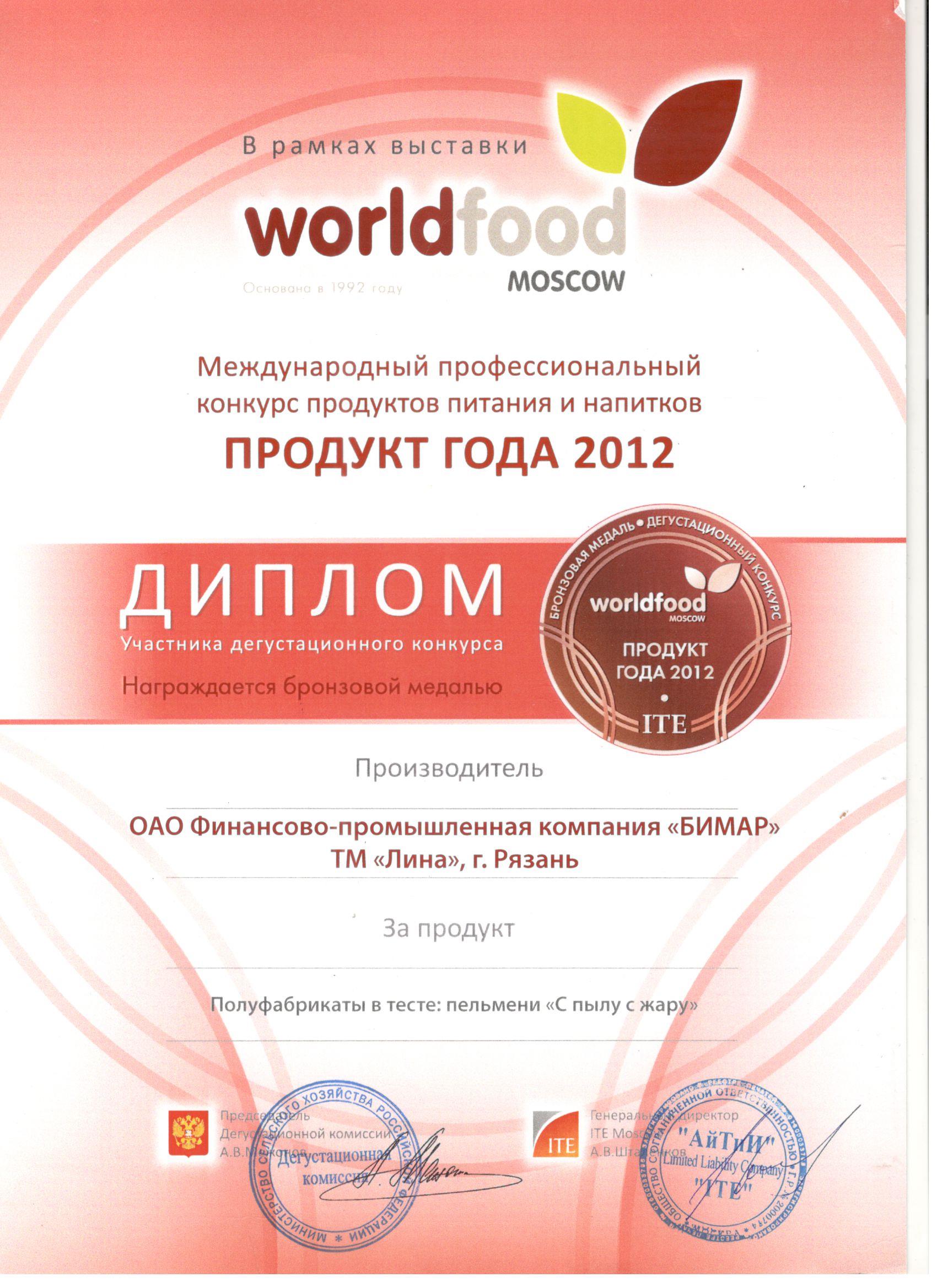

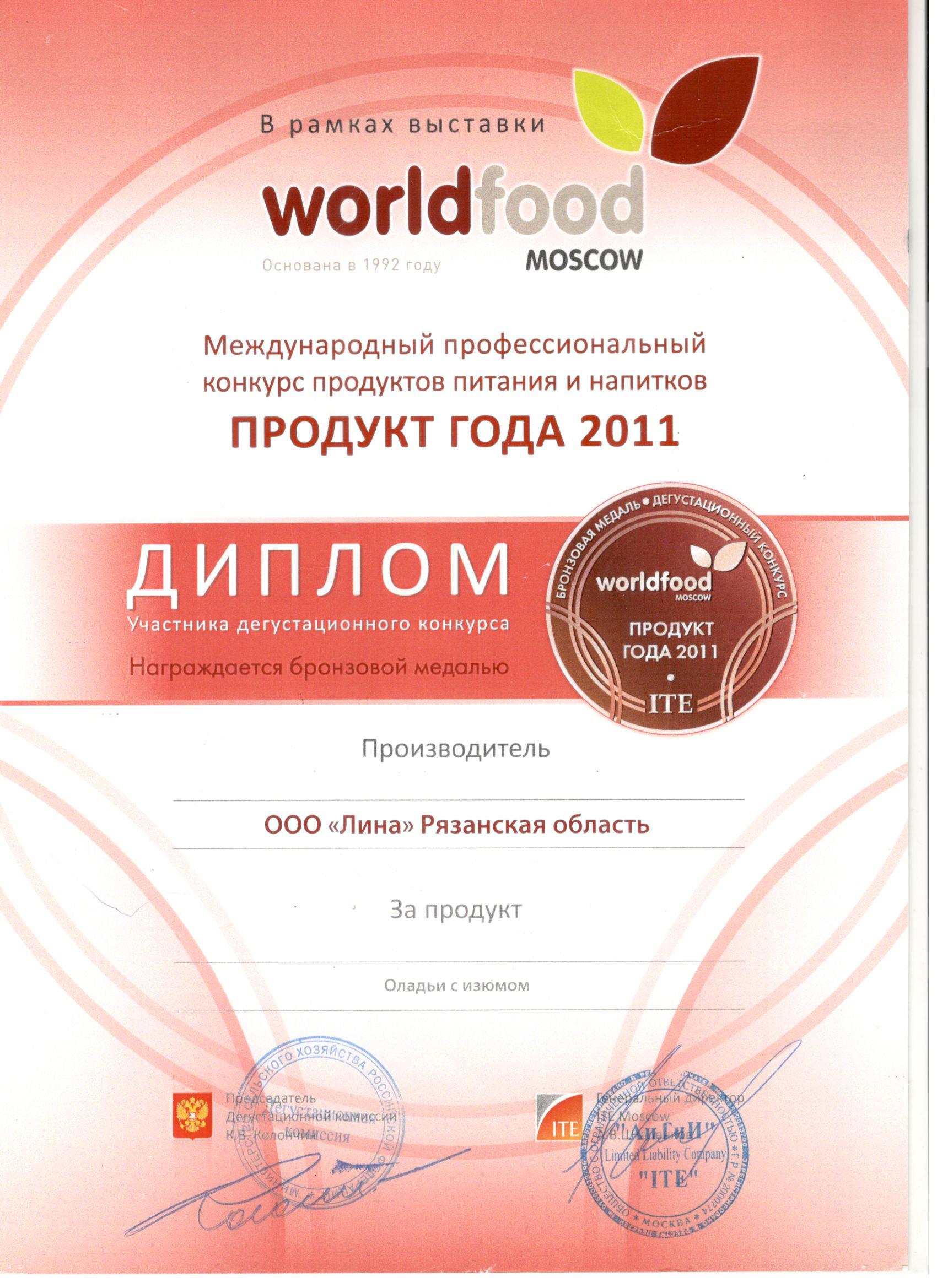

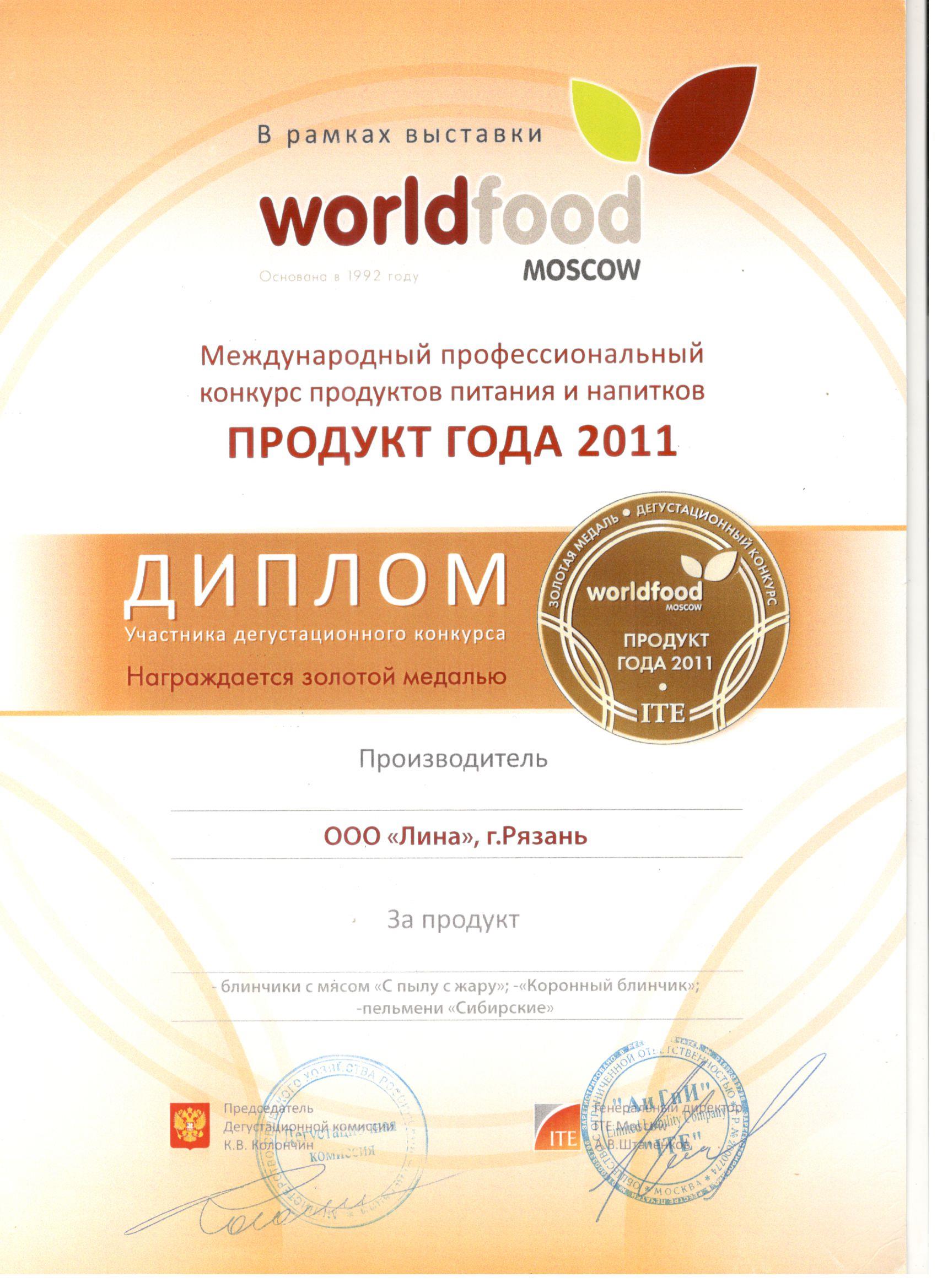

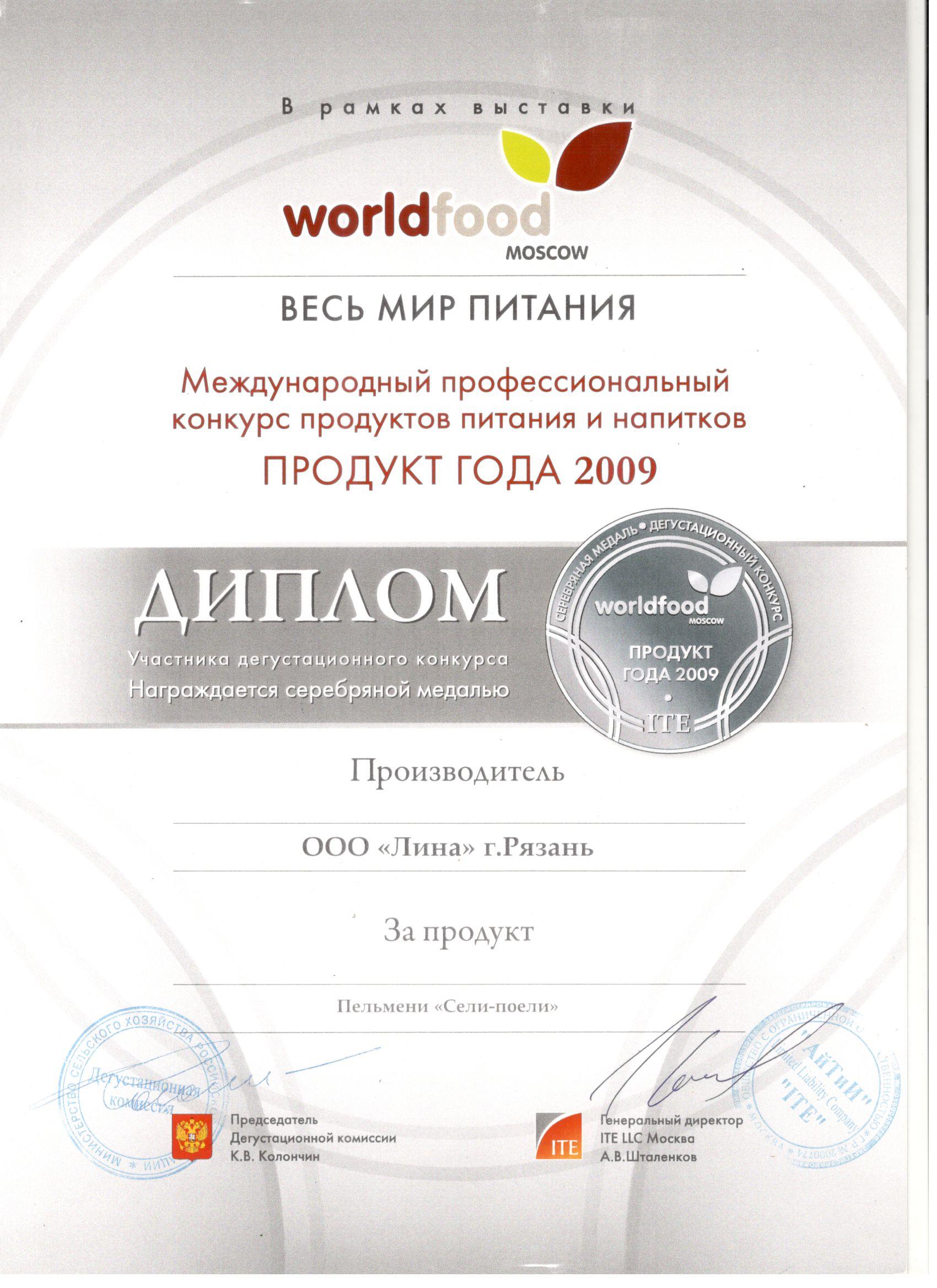

Quality assurance

So that both we and you are confident in the quality of our products, we receive certificates of conformity with European industry standards. One of the most important is Food Safety System Certification. Food Safety).

Why is it important

He makes sure that the company can regularly achieve high quality work. Experts do not analyze the product itself, because it may differ from batch to batch, but the management system of the company. If all processes, from planning to control within the organization are adjusted correctly, then the quality will be stable and high.

FSSC 22000 certificate shows that the main goal of the company is to produce safe and always high quality products.

Who carried out the certification

Compliance with all our requirements were confirmed by two European independent centers at once - QSCert (Czech Republic) and SGS (Great Britain). Each of them issued us a certificate of compliance with all FSSC 22000 requirements.